In the high-stakes world of industrial processing, the performance and reliability of your pumping systems are paramount. Faced with a constant barrage of aggressive fluids, abrasive particulates, and demanding environmental conditions, industrial pumps must be engineered to withstand the toughest challenges with unwavering resilience. At the heart of this engineering marvel lies a material that has long been the unsung hero of the industry – stainless steel.

Unlocking the Transformative Power of Stainless Steel

Stainless steel has long been the material of choice for industrial pump manufacturers, and for good reason. This versatile alloy, crafted from a unique blend of iron, chromium, and other essential elements, offers a suite of unparalleled properties that make it the perfect fit for the rigors of industrial applications.

Corrosion Resistance: The First Line of Defense

One of the primary reasons why stainless steel is so widely used in industrial pumps is its exceptional resistance to corrosion. The chromium content in stainless steel forms a thin, invisible layer of chromium oxide on the surface of the material, acting as a barrier against the intrusion of corrosive elements. This makes stainless steel an ideal choice for pumping a wide range of aggressive fluids, from harsh chemicals and caustic solutions to corrosive acids and alkalis.

In industries where product purity and safety are of the utmost importance, such as food processing and pharmaceuticals, the corrosion resistance of stainless steel is particularly crucial. food grade stainless steel pumps, for example, are engineered to maintain the integrity of sensitive products by preventing the leaching of harmful contaminants and ensuring a seamless, uninterrupted flow.

Durability and Longevity: Withstanding the Test of Time

In addition to its impressive corrosion resistance, stainless steel also boasts exceptional durability and longevity. This hardy material is able to withstand the rigors of heavy-duty industrial use, including exposure to high temperatures, intense pressure, and abrasive wear. By incorporating stainless steel components into their pump designs, manufacturers can ensure that their products will maintain peak performance for years to come, minimizing costly downtime and maintenance requirements.

This durability is particularly valuable in industries where equipment failure can lead to significant financial and operational consequences, such as mining, oil and gas, and power generation. In these high-stakes environments, stainless steel pumps offer a reliable and long-lasting solution, providing peace of mind and ensuring the smooth, uninterrupted operation of critical processes.

Hygienic and Easy-to-Clean Design: Maintaining the Highest Standards

Beyond its impressive physical properties, stainless steel also offers significant advantages in terms of hygiene and cleanability. The smooth, non-porous surface of stainless steel makes it resistant to the buildup of contaminants, bacteria, and other microorganisms, which is crucial in industries where maintaining the highest standards of cleanliness is paramount.

In the food and beverage industry, for example, stainless steel food grade pumps are designed with sanitary features that enable easy cleaning and sterilization, ensuring the integrity and purity of the products being handled. This not only safeguards consumer health and safety but also helps to extend the lifespan of the equipment by preventing the accumulation of harmful deposits and corrosive agents.

Expanding the Possibilities with Stainless Steel Pump Design

The versatility of stainless steel extends far beyond its inherent material properties, as industrial pump manufacturers have leveraged this remarkable material to develop a wide range of innovative design features and specialized solutions.

Customizable and Adaptable

One of the key advantages of stainless steel in industrial pump design is its high degree of customizability. Pump manufacturers can tailor the composition, thickness, and surface finish of stainless steel components to meet the specific requirements of each application, ensuring optimal performance and longevity.

This adaptability is particularly valuable in industries where process conditions and fluid properties can vary widely, such as chemical processing and wastewater treatment. By selecting the appropriate stainless steel grade and design, pump engineers can create highly specialized solutions that can handle a diverse range of challenging fluids and operating environments.

Innovative Features and Functionalities

The inherent properties of stainless steel have also enabled pump manufacturers to develop a wide range of innovative features and functionalities that push the boundaries of industrial pump design. From advanced sealing systems that enhance leak prevention to high-efficiency impeller designs that optimize flow and energy consumption, stainless steel has played a pivotal role in driving the evolution of industrial pumping technology.

In the realm of food grade pumps, for example, stainless steel has been instrumental in the development of CIP (Cleaning-in-Place) and SIP (Sterilization-in-Place) capabilities, which allow for the efficient and thorough cleaning of pump components without the need for disassembly. This not only streamlines maintenance and reduces downtime but also helps to ensure the highest levels of product purity and safety.

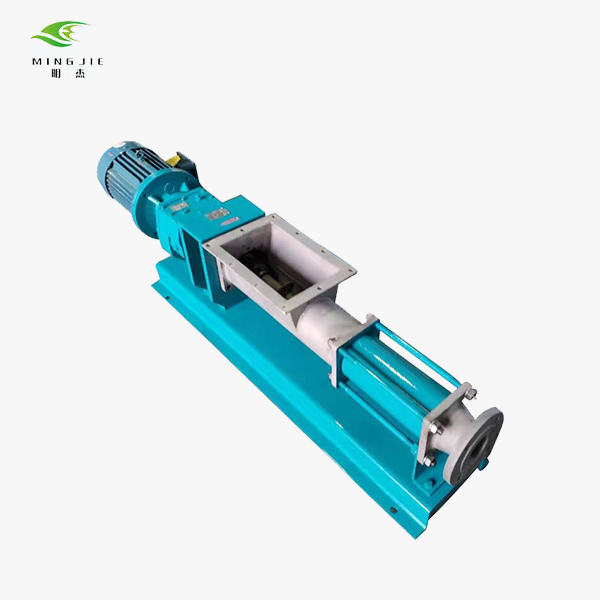

Partnering with Industry Leaders for Unparalleled Pump Solutions

As the industrial landscape continues to evolve, the demand for high-performance, durable, and hygienic pumping solutions has never been greater. Recognizing this, leading pump manufacturers have invested heavily in the development of stainless steel-based technologies, leveraging their expertise and innovative capabilities to deliver cutting-edge solutions that cater to the unique needs of various industries. For more information on stainless steel pumps, Mingjiepump is a good place to go or click here for detailed videos.